Tungsten Metal Powder

How are metal powders maked?

The first step in the overall PM process is making metal powders. There are four main processes used in powder production: solid-state reduction, atomization, electrolysis, and chemical.

Solid-state reduction

In solid-state reduction, selected ore is crushed, mixed with a reducing species (e.g., carbon), and passed through a continuous furnace. In the furnace, a reaction takes place that leaves a cake of sponge metal which is then crushed, separated from all non-metallic material, and sieved to produce powder. Since no refining operation is involved, the purity of the powder is dependent on the purity of the raw materials. The irregular sponge-like particles are soft, readily compressible, and give compacts of good pre-sinter (“green”) strength.

Atomization

In this process, molten metal is separated into small droplets and frozen rapidly before the drops come into contact with each other or with a solid surface. Typically, a thin stream of molten metal is disintegrated by subjecting it to the impact of high-energy jets of gas or liquid. In principle, the technique is applicable to all metals that can be melted and is used commercially for the production of iron; copper; alloy steels; brass; bronze; low-melting-point metals such as aluminum, tin, lead, zinc, and cadmium; and, in selected instances, tungsten, titanium, rhenium, and other high-melting-point materials.

Electrolysis

By choosing suitable conditions, such as electrolyte composition and concentration, temperature, and current density, many metals can be deposited in a spongy or powdery state. Further processing–washing, drying, reducing, annealing, and crushing–is often required, ultimately yielding high-purity and high-density powders. Copper is the primary metal produced by electrolysis but iron, chromium, and magnesium powders are also produced this way. Due to its associated high energy costs, electrolysis is generally limited to high-value powders such as high-conductivity copper powders.

Chemical

The most common chemical powder treatments involve oxide reduction, precipitation from solutions, and thermal decomposition. The powders produced can have a great variation in properties and yet have closely controlled particle size and shape. Oxide-reduced powders are often characterized as “spongy,” due to pores present within individual particles. Solution-precipitated powders can provide narrow particle size distributions and high purity. Thermal decomposition is most often used to process carbonyls. These powders, once milled and annealed, exceed 99.5 percent purity.

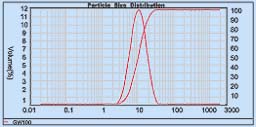

Specification:

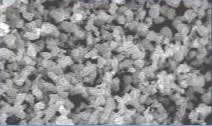

Ultra-fine and sub-micro powder

GW04 X7000

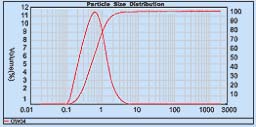

1μ to 9μ powder

GW60 X1200

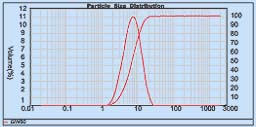

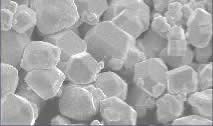

Coarse powder

GW100 X1000

Packing: in plastic bag with outer iron drums of 50/100kgs net each.

If you have any interest in our products, please feel free to contact us by email: sales@chinatungsten.com or by telephone:+86 592 5129696.

sales@chinatungsten.com;

sales@chinatungsten.com;